12mm Polypropylene Fiber Mixed in ConcreteQuality Compliance EN-14889-2Polypropylene Micro fiber is one kind of Concrete Fiber and Polypropylene Fiber, it is 100% new polypropylene as the main raw material, adopting unique manufacturing process to make high strength bundle monofilament fiber.

Contact Now

Product DetailsInside the concrete combination, add proper amount steel fiber may be mixed into a type of special jetting as well as casting concrete, specifically metal fiber bolstered concrete.In comparison with fashionable concrete, metallic fiber concrete has high-quality development in tensile strength, flexural strength, abrasion resistance, effect resistance, fatigue resistance, sturdiness, crack resistance and antiknock overall performance, due to the fact huge quantity of very minute steel fiber is frivolously dispersed within the concrete and has a massive contact place with concrete

Contact Now

In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.Compared with general concrete, Carton steel fiber concrete has great improvement in tensile strength, flexural strength, abrasion resistance, impact resistance, fatigue resistance, toughness,crack resistance and antiknock performance, because large number of very minute steel fiber is evenly dispersed in the concrete and has a large contact area with concrete, therefore, concrete strength is improved i

Contact Now

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

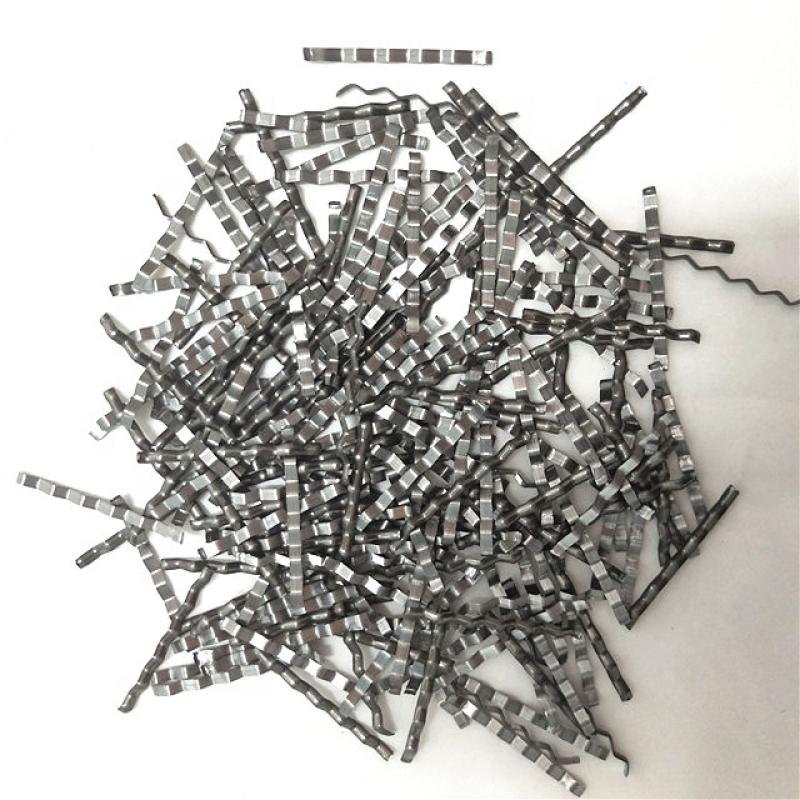

Carbon Steel Milling Fiber For Concrete and Cement In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.

Contact Now

Product Details Within the concrete aggregate, upload right amount metallic fiber can be mixed into a sort of unique jetting in addition to casting concrete, particularly metal fiber bolstered concrete. As compared with popular concrete, metallic fiber concrete has superb improvement in tensile strength, flexural power, abrasion resistance, effect resistance, fatigue resistance, durability, crack resistance and antiknock performance, due to the fact big wide kind of very minute metal fiber is frivolously dispersed within the concrete and has a huge contact vicinity with concrete, co

Contact Now

Product Details With polypropylene fiber as its raw cloth, curved pp macro fiber is produced with the aid of special molding technique and floor modification; it has gain of acid, alkali resistant, exceptional tensile, easy dispersing, convenience for construction and no damage to automobiles and pavement and no need for unique conservation. Curved pp macro fiber can be used rather than steel fiber to beautify the crack resistance of cement concrete and substantially enhance the longevity and flexural of concrete.

Contact Now