Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Contact Now

4 MM -19 MM Polypropylene PP Concrete Reinforced Fibers Polypropylene fiber can improve the adhesion of concrete, reduce cracks of concrete in the early stage. As our experiments, only 0.1% fibers by volume can improve the cracking resistance by 70%, and the impermeability increases by 60%-70%. PP fibers are chemically stable, it has excellent corrosive resistance to expand the self-life of your projects. PP fiber increases impermeability, only 0.9Kg/m3 PP fibers can improve it by 70%. The light-weight (0.91 density) of PP fib

Contact Now

Product Details When the fiber is put into the concrete, the horizontal structure in fiber monofilament may be destroyed inside the course of stirring attributable to friction and rubbing, and the fiber monofilament or net-like shape will completely stretch, consequently the concrete is reinforced by using a remarkable quantity of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)100±50Material100% polypropyleneCrack Elongation(%)≥16Water-AbsorbencyNoMelting Point160-170

Contact Now

High Strength 100 mm HDPE GeocellsGeocell is a network structure made of high-density polyethylene and other materials, the material is light, wear resistance, chemical stability, light oxygen aging and acid and alkali corrosion resistance, suitable for different soil and climate conditions.The HDPE geocell is widely used in road, railway, water conservancy, garden chemical industry and other fields, which can effectively provide the stability and durability of the project.

Contact Now

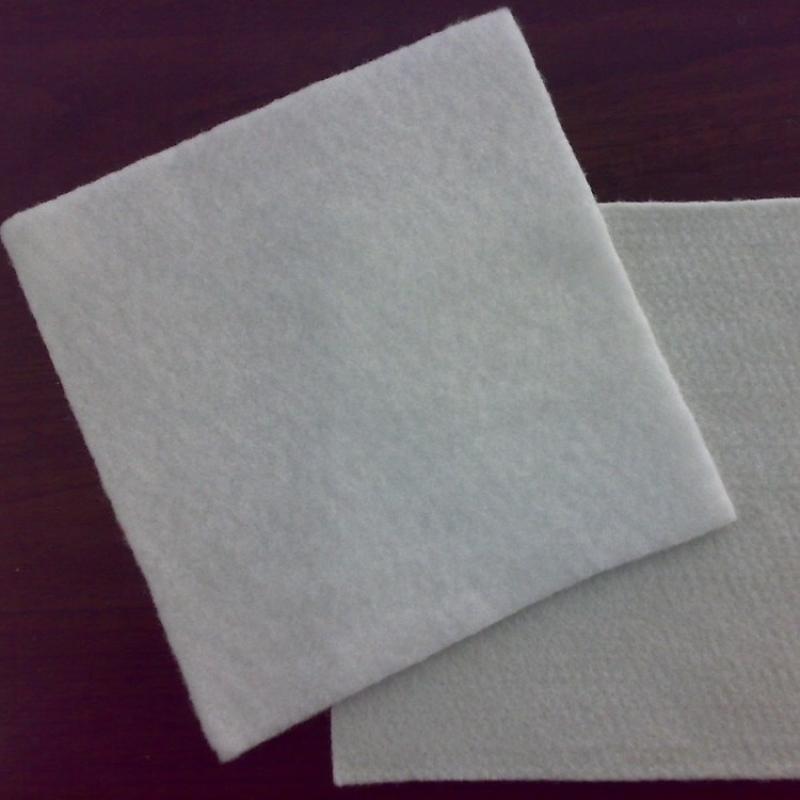

Filament Polyester Non-woven GeotextilePolyester filament geotextile is also called filament non-woven geotextile/polyester non-woven geotextile.The filament non woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is kind of new material in geotechnical and engineering project.Expect for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkail resistance and antiaging.Main function of filament polyester geotextile:1、Filament polyester geotextile can play a

Contact Now

Product DetailsReinforced 3D Geomat Erosion Control Mat for Soil Stabilization Slope Protection Geomat3D geomat is sort of a gourd community three-dimensional shape for the planting soil, unfastened and bendy, with a 90% space filling soil,gravel and excellent stone, plant roots can interfere, at ease, orderly and balanced increase after growing grass mat, turf, soil.The surface tightly collectively, because the plant roots deep below the floor of 30 - 40 cm, forming a defensive layer of inexperienced composite strong.Before the turf grows, it protects the surface of the soil fr

Contact Now