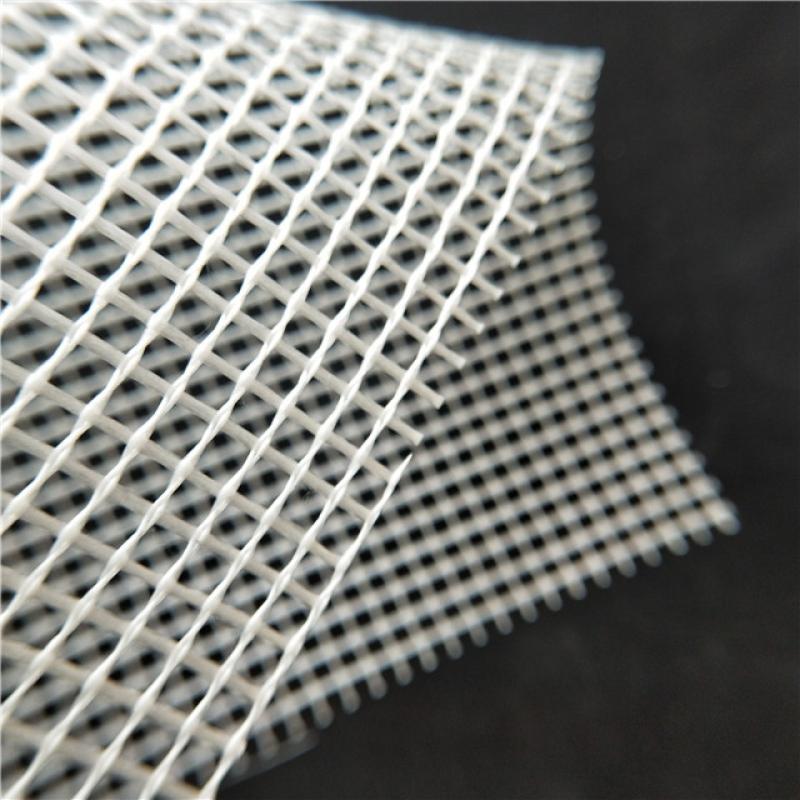

Fiberglass Mesh Fabric Fiberglass mesh is woven by C-glass fiberglass yarn, and then coated by alkali resistant glue.mainly has high property for acid-resistant and high strength for concrete reinforcement. Fiberglass mesh has been the main basic materials for constructions, and welcomed in Europe.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass

Contact Now

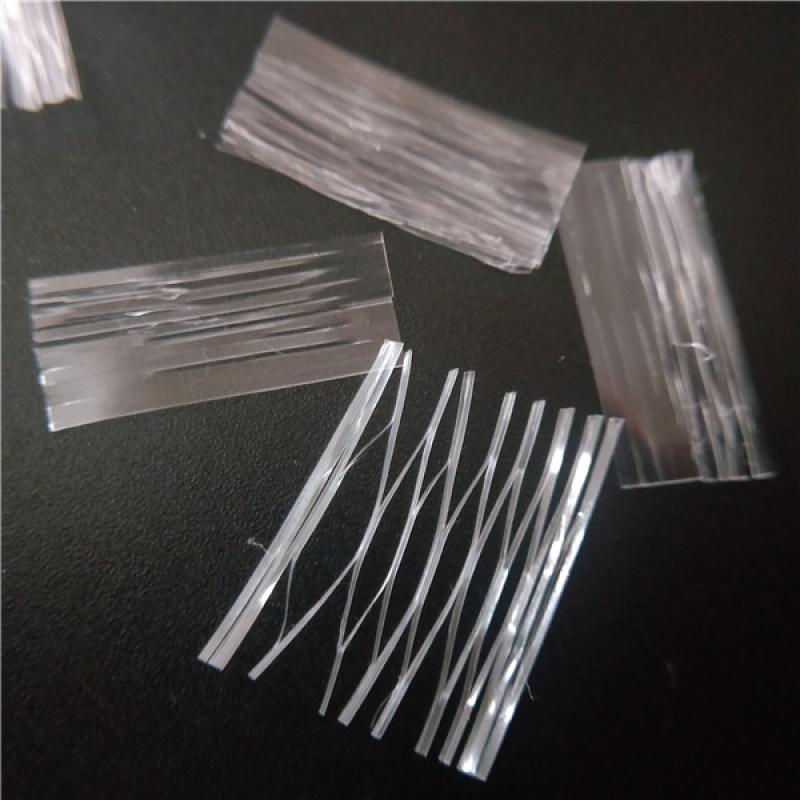

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

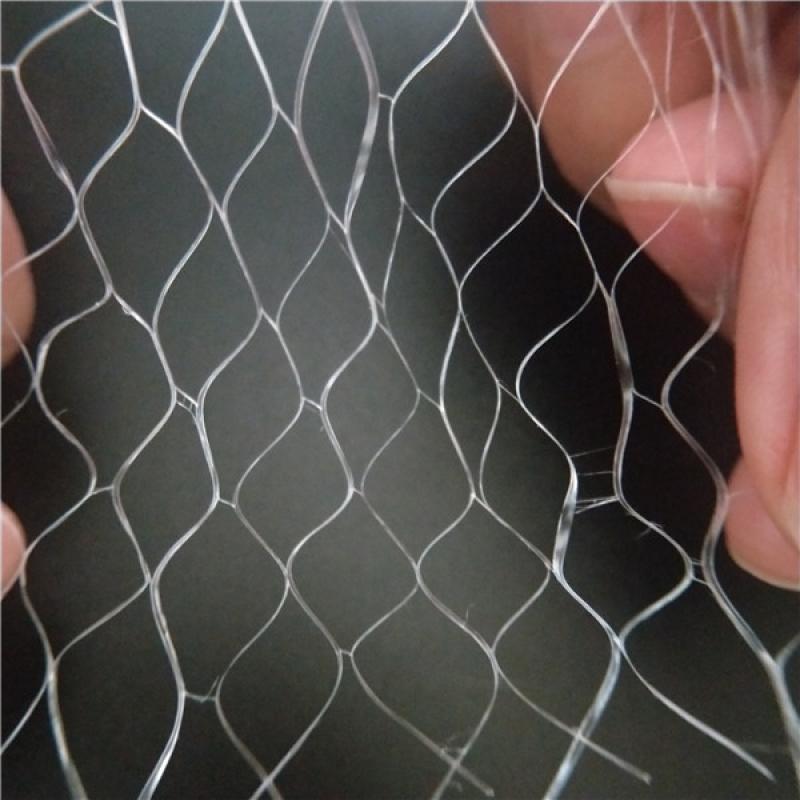

Fibrillated Mesh Polypropylene Fibre for Concrete ReinforcementThis is Fibrilled Mesh Polypropylene Fiber for Concrete.It appears net-like structure with many monofilaments connected.ApplicationConcrete pavement,deck,airport runway,factory horizon. Shotcrete projects such as tunnel,mine wall,roof.Irrigation work such as river,dam.Military protection,terminal revetment, bridge pier.Concrete precast

Contact Now

Hot Sale Reinforced Fiberglass Alkali Resistant Mesh Netting Fabric For Concrete Fiberglass mesh is woven by way of c-glass fiberglass yarn, after which coated via alkali resistant glue.specifically has high assets for acid-resistant and excessive power for concrete reinforcement. Which has properly alkali resistance, flexibility and robust tensile strength, it can be extensively utilized in exterior insulation finishing system (eifs), roofing machine, marble, and many others.1.Factor

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

Price Polypropylene Mesh Fiber for ConcreteProduct Details While the fiber is put into the concrete, the horizontal structure in fiber monofilament can be destroyed in the path of stirring as a consequence of friction and rubbing, and the fiber monofilament or net-like shape will completely stretch, consequently the concrete is strengthened through using a great quantity of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensil

Contact Now

80-160 G Fiberglass Mesh Fabric For Wall Construction Fiberglass mesh is woven by means of c-glass fiberglass yarn, and then coated by way of alkali resistant glue.specifically has excessive property for Acid-resistant and excessive electricity for concrete reinforcement.Fiberglass mesh has been the primary simple materials for structures, and welcomed in europe.1.Factory supply2.Quick deliver

Contact Now

China Supplier Polypropylene Mesh Fiber for ConcreteProduct DetailsWhile the fiber is positioned into the concrete, the horizontal structure in fiber monofilament can be destroyed in the direction of stirring.As a result of friction and rubbing, and the fiber monofilament or internet-like form will absolutely stretch, therefore the concrete is strengthened via the usage of a brilliant amount of polypropylene fibers.ParameterDensity(g/cm³)0

Contact Now

80-160 G Fiberglass Mesh Fabric For Wall Construction Fiberglass mesh is woven with the aid of c-glass fiberglass yarn, after which coated by means of way of alkali resistant glue.specially has immoderate assets for acid-resistant and immoderate energy for concrete reinforcement. Fiberglass mesh has been the number one simple substances for systems, and welcomed in europe.1.Factory

Contact Now

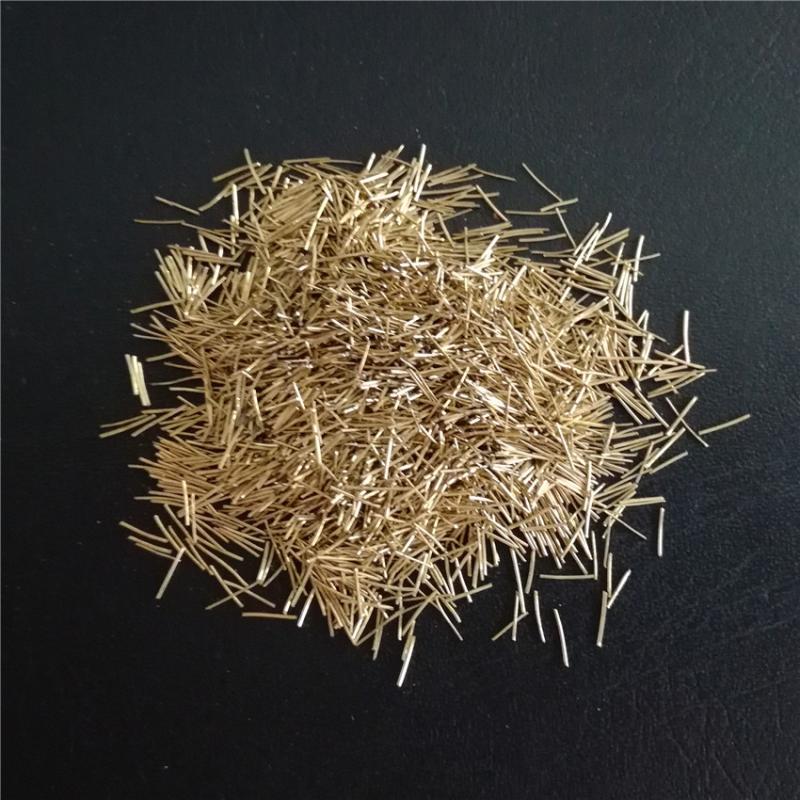

It‘s the special kind of metal fiber with very high of compressive intensity, tensile intensity, crack resistance.It is widely uesd in high-speed rail precast,RPC cover Board,important projects components and exterior painting. It can improve the performances of the conceret,such as anti-tensile, anti-compressive,shear intensity,impermeability,impact resistance,fatigue resistance,and so on. Tensile Strength > 2800MPA0.2 ~0.3mm diameterLength as your requestApplication Its widely used in highway, bridge, tunnel, airport runway, industrial floor, hydraulic project and bas

Contact Now