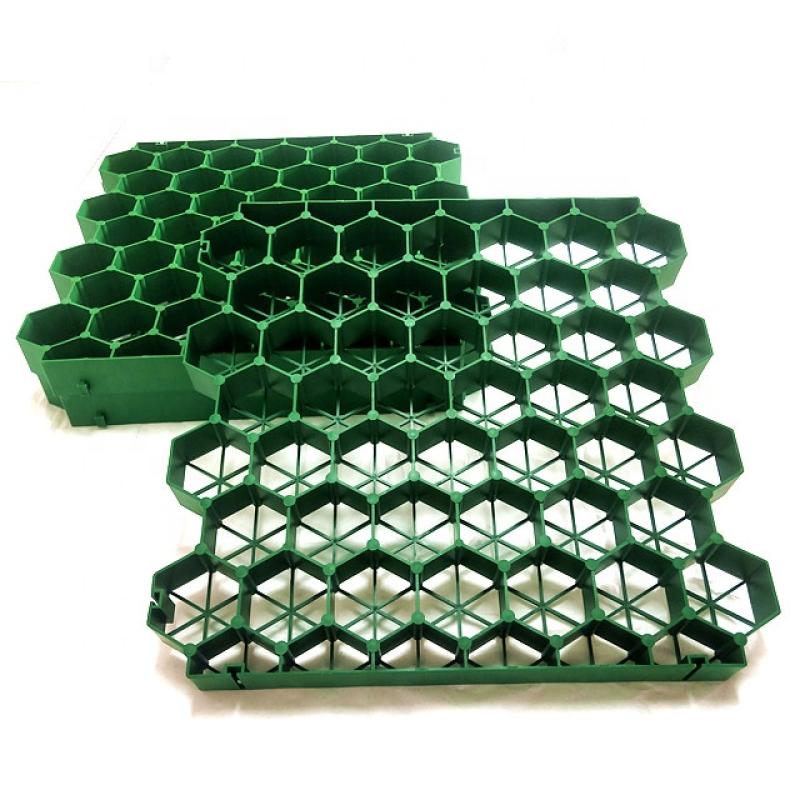

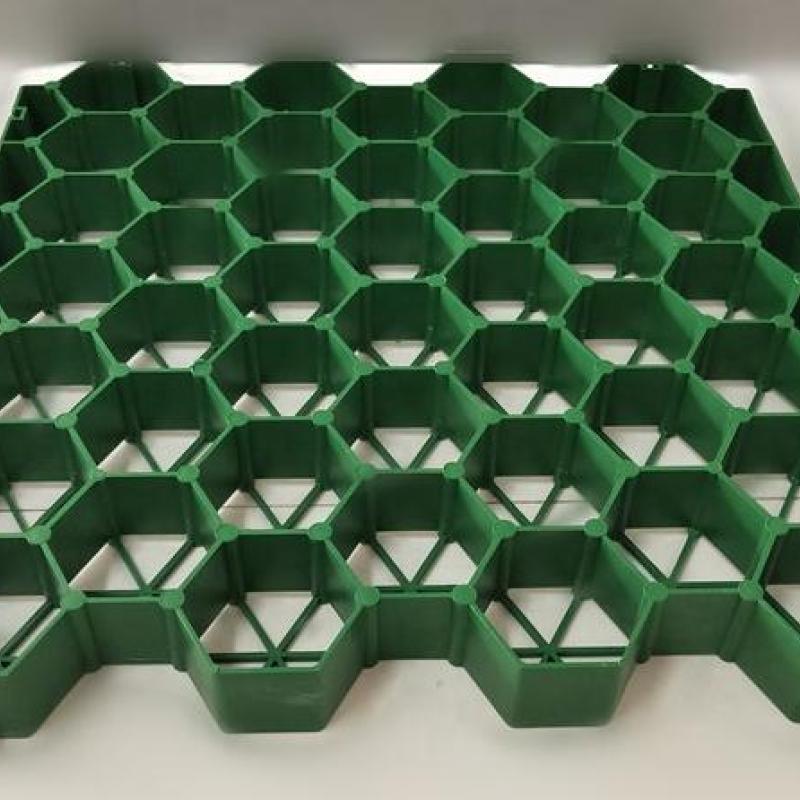

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Contact Now

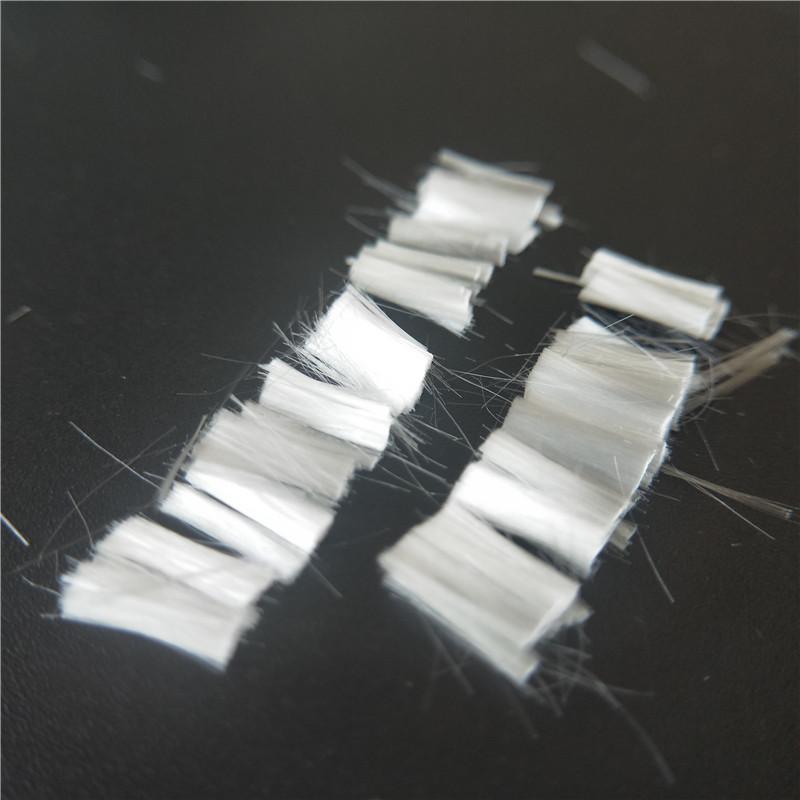

Product Details Whilst the fiber is positioned into the concrete, the horizontal structure in fiber monofilament may be destroyed inside the direction of stirring due to friction and rubbing, and the fiber monofilament or net-like form will absolutely stretch, therefore the concrete is bolstered thru the usage of a outstanding amount of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)100±50Material100% polypropyleneCrack Elongation(%)≥16Water-AbsorbencyNoMelti

Contact Now

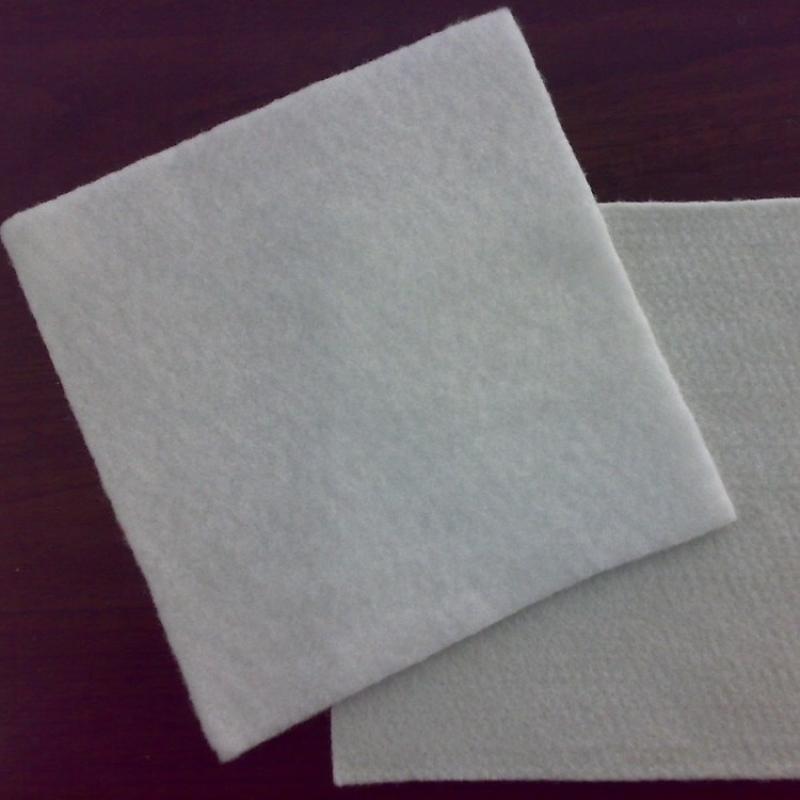

Filament Polyester Non-woven GeotextilePolyester filament geotextile is also called filament non-woven geotextile/polyester non-woven geotextile.The filament non woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is kind of new material in geotechnical and engineering project.Expect for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkail resistance and antiaging.Main function of filament polyester geotextile:1、Filament polyester geotextile can play a

Contact Now

High Quality Polypropylene Fibers Micro Fiber Mortar FiberPolypropylene fiber is a synthtic pp fiber,is made of polypropylene as its main material.It has the characteristics of light weight,wear resistance,corrosion resistance ,mildew resistance and so on.

Contact Now

Product Details With polypropylene fiber as its raw cloth, curved pp macro fiber is produced with the aid of special molding technique and floor modification; it has gain of acid, alkali resistant, exceptional tensile, easy dispersing, convenience for construction and no damage to automobiles and pavement and no need for unique conservation. Curved pp macro fiber can be used rather than steel fiber to beautify the crack resistance of cement concrete and substantially enhance the longevity and flexural of concrete.

Contact Now

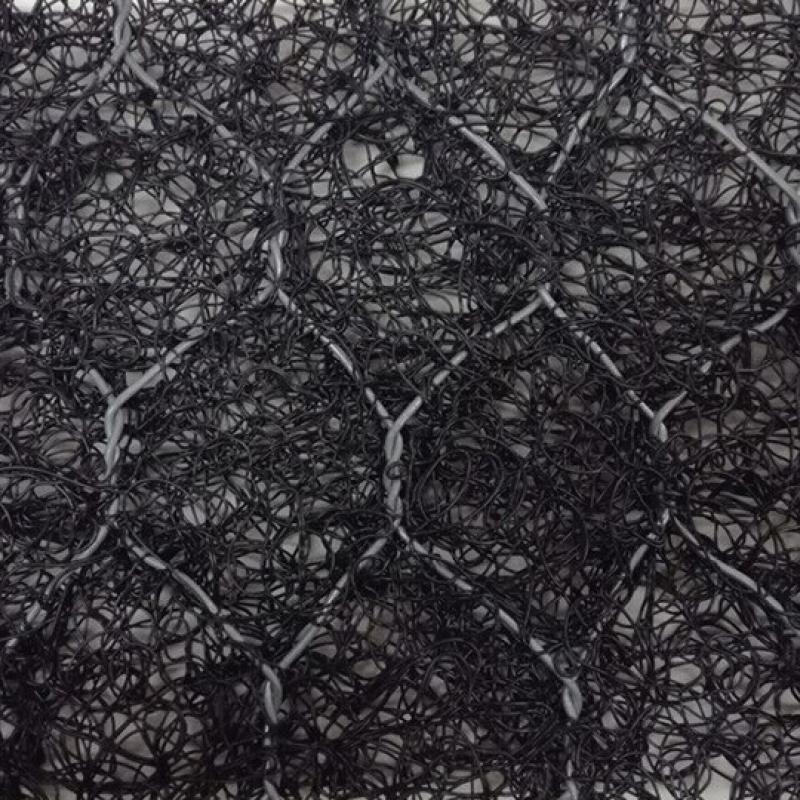

Product DetailsThe Reinforced Geomat is PP mesh mat composited with wire mesh, which is galvanized in case of erosion control.The structure allows enough space for keeping the soil and grass growing.

Contact Now

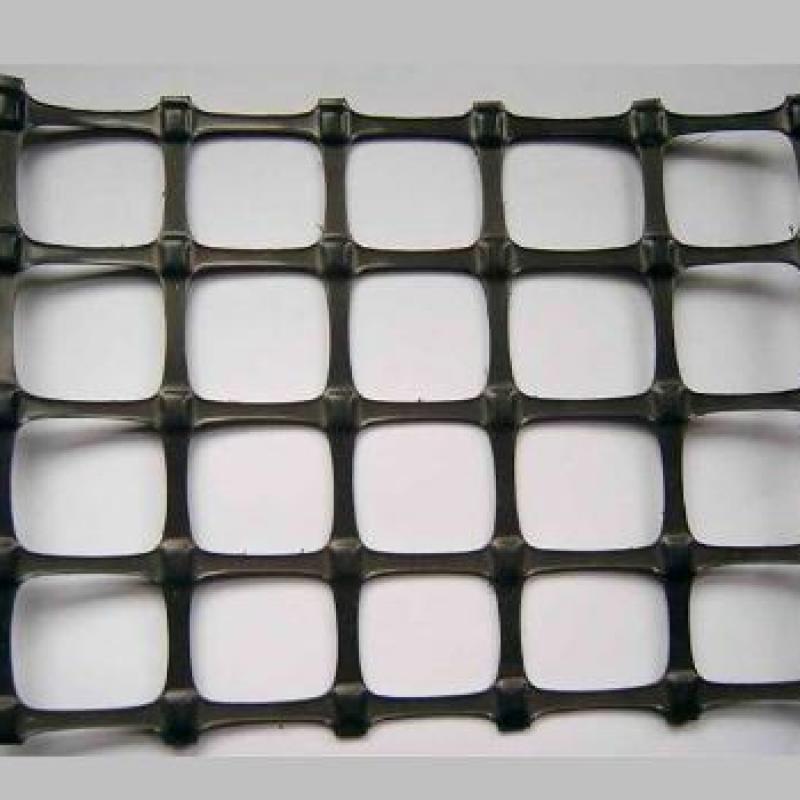

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Contact Now

HDPE Dimple Drainage Board For Construction ProjectsConstruction drainage board mainly includes polyethylene, polypropylene and polyvinyl chloride and other plastic materials. HDPE drainage board is mainly made of high density polyethylene material, with high compressive strength, good flatness characteristics. Its surface is continuous and orderly concave and convex, which can effectively drain and store water, and has the characteristics of anti-acid, alkali and salt corrosion, anti-aging and anti-weathering, etc.

Contact Now

High Density Polyethylene Drainage Dimple Board SheetThe high-density drainage plate adopts a special process to press the plastic sheet into many closed and prominent cylindrical shells, forming a concave-convex membrane shell connection, with three-dimensional space and a certain height.

Contact Now

Water-permeable Staple Fiber Needle Non-woven GeotextilePP PET Non-woven geotextile is a kind of water-permeable geosynthetic material made of synthetic fibers by needling or weaving.It is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness.The main function is filtration,darange,rein forcement.water-permeable staple fiber needle punched geotextile has good impermeability and resistance to deformation.Technical parameter of geotextile:Test PropertiesUnitsLKS10LKS15LKS20LKS25LKS30LKS35LKS40LKS45LKS50LKS60LKS80Mechanical PropertiesWeigh

Contact Now