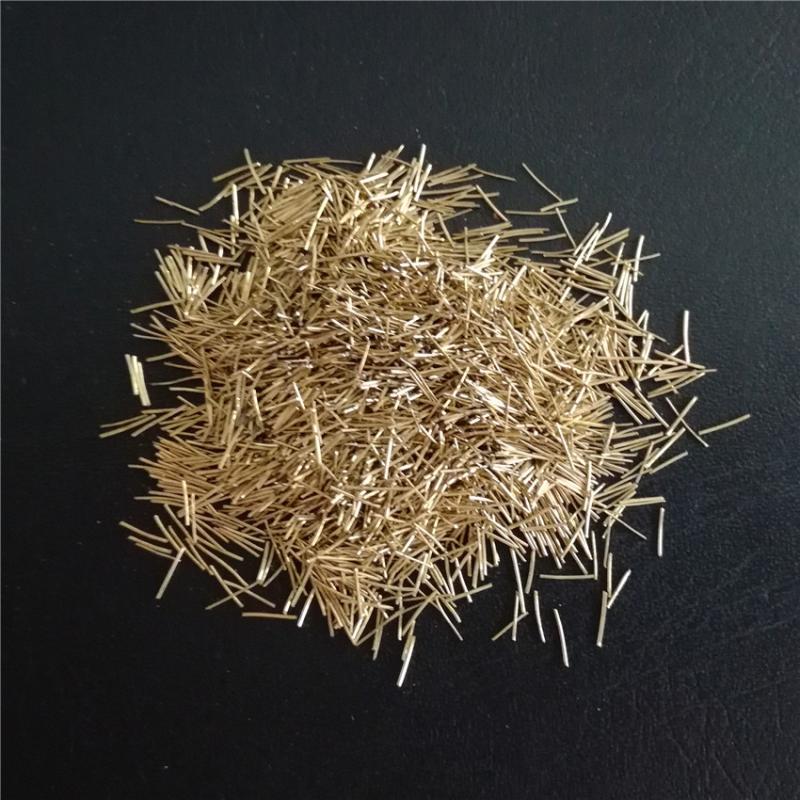

Carbon Steel Milling Fiber For Concrete and Cement In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.

Contact Now

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Contact Now

It‘s the special kind of metal fiber with very high of compressive intensity, tensile intensity, crack resistance.It is widely uesd in high-speed rail precast,RPC cover Board,important projects components and exterior painting. It can improve the performances of the conceret,such as anti-tensile, anti-compressive,shear intensity,impermeability,impact resistance,fatigue resistance,and so on. Tensile Strength > 2800MPA0.2 ~0.3mm diameterLength as your requestApplication Its widely used in highway, bridge, tunnel, airport runway, industrial floor, hydraulic project and bas

Contact Now

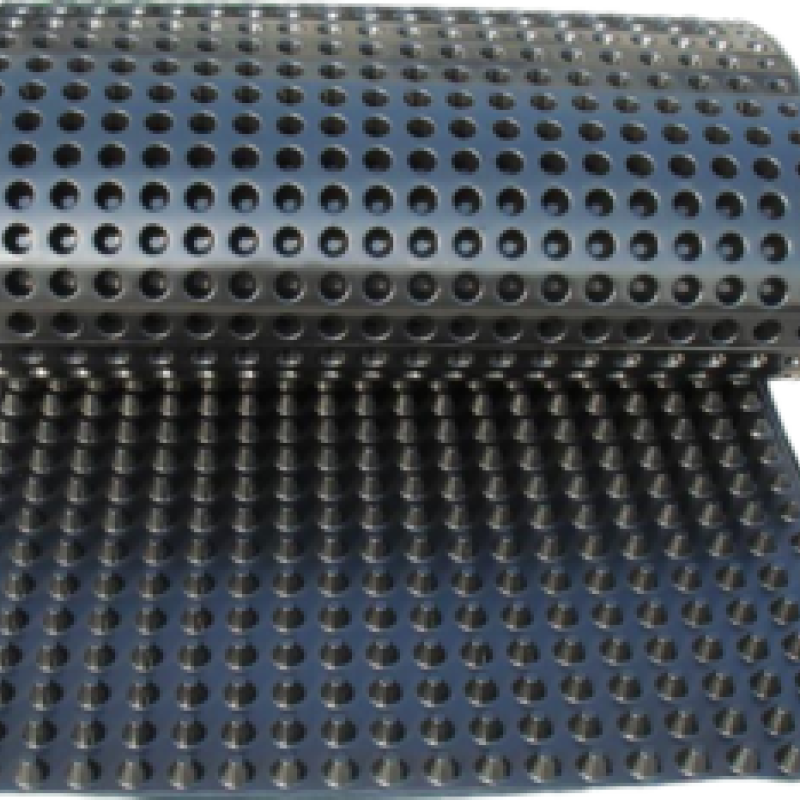

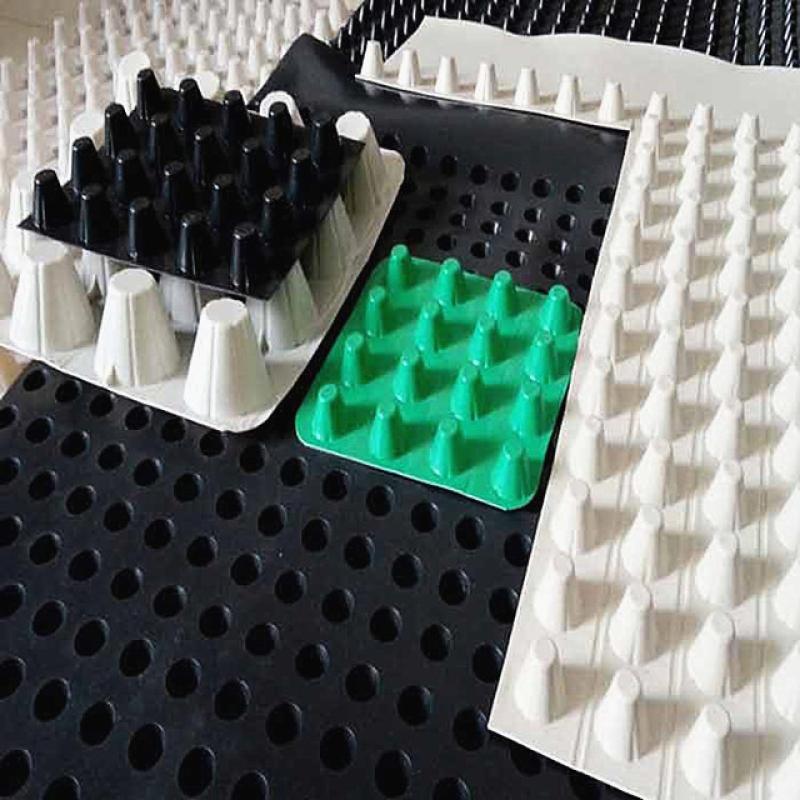

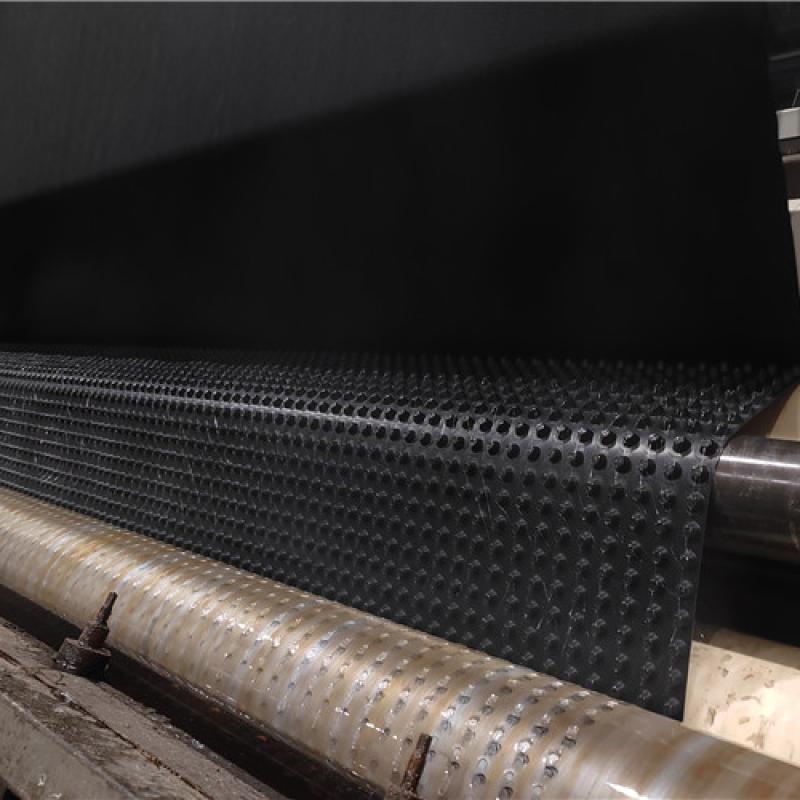

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Contact Now

Plastic Fiber For Cement Curved Macro PP FiberProduct Details With polypropylene fiber as its uncooked material, curved pp macro fiber is produced with the aid of special molding manner and surface modification. It has advantage of acid, alkali resistant, amazing tensile, smooth dispersing, comfort for construction and no harm to vehicles and pavement and no want for unique conservation. Curved pp macro fiber

Contact Now

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

Product Details With polypropylene fiber as its raw cloth, curved pp macro fiber is produced with the aid of special molding technique and floor modification; it has gain of acid, alkali resistant, exceptional tensile, easy dispersing, convenience for construction and no damage to automobiles and pavement and no need for unique conservation. Curved pp macro fiber can be used rather than steel fiber to beautify the crack resistance of cement concrete and substantially enhance the longevity and flexural of concrete.

Contact Now

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Contact Now

Product DetailsComposite drainage net is made from geonet bonding layers of geotextile which combines the homes of geotextile filtration and geonet drainage and safety,providing entire“inverted clear out drainage to shield”effect.drainage nets center is extruded by way of excessive density polyethylene uncooked materials adding carbon black and ultraviolet and antioxidant stabilizer.the interlaced net office work right into a drainage channel which has fantastic vertical drainage residences.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6

Contact Now

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Contact Now