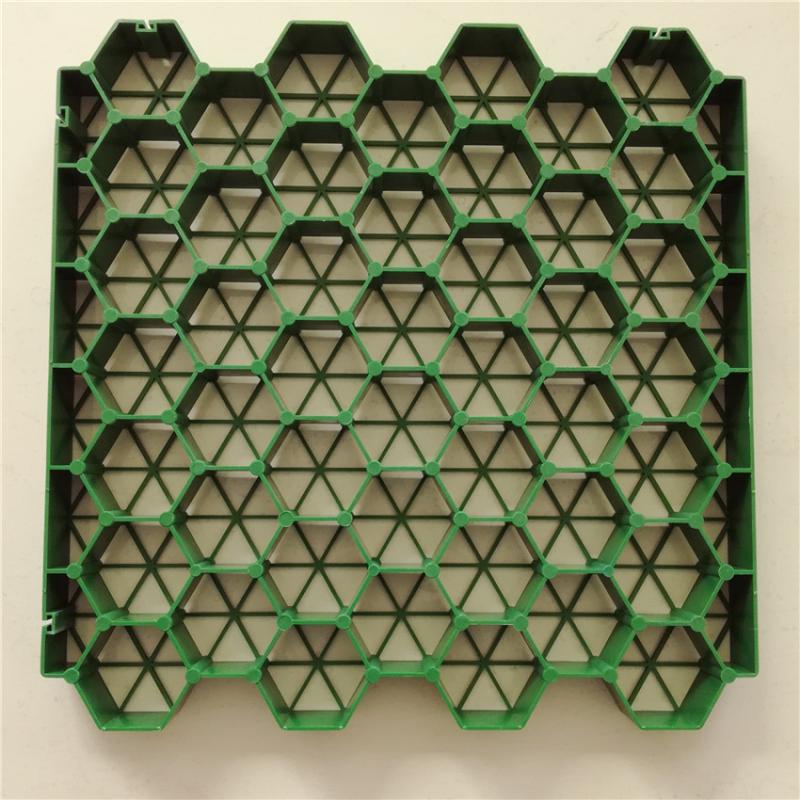

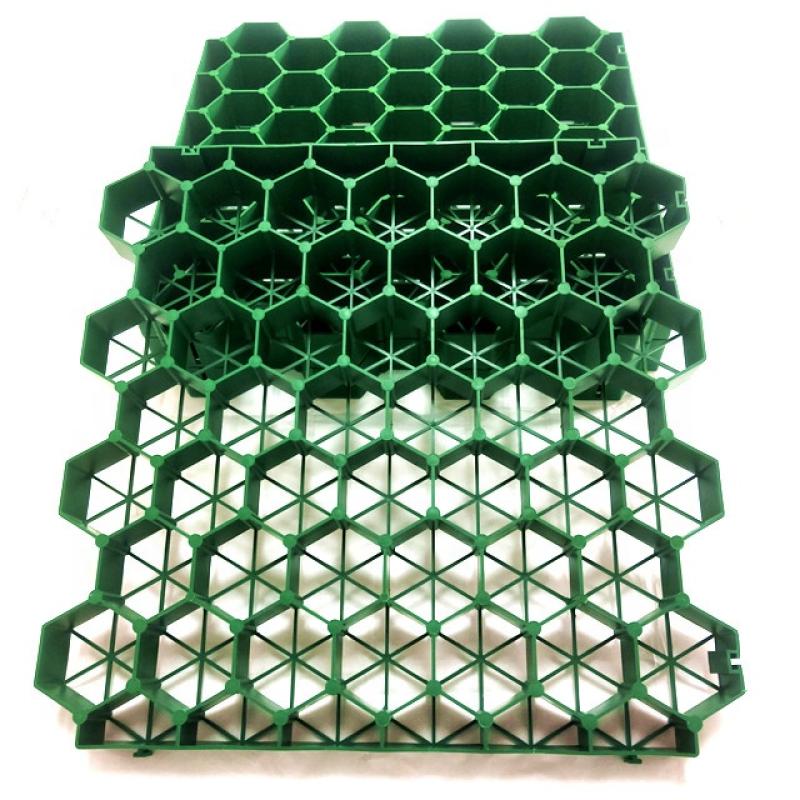

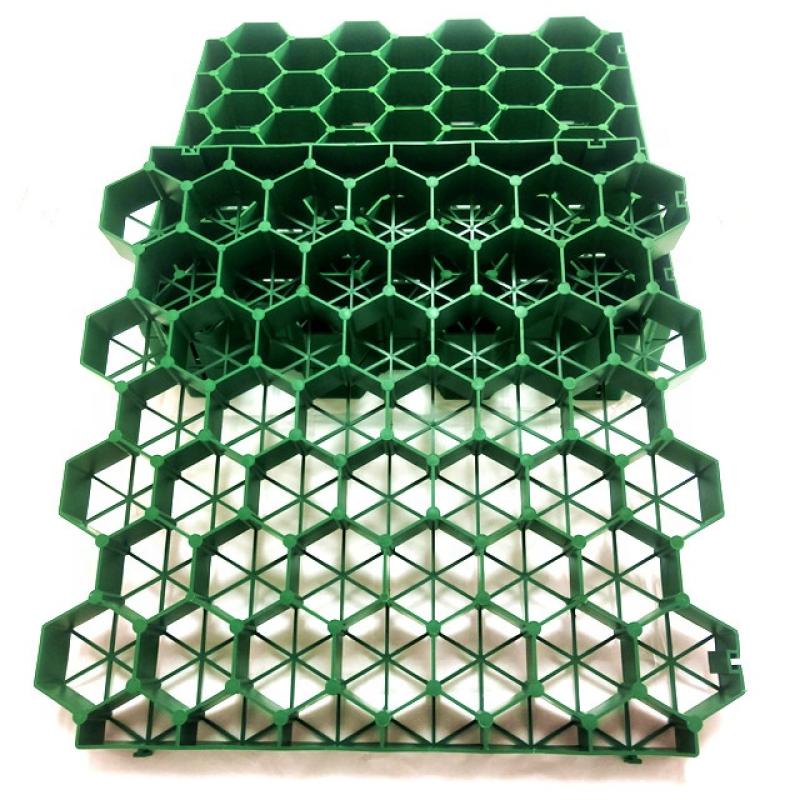

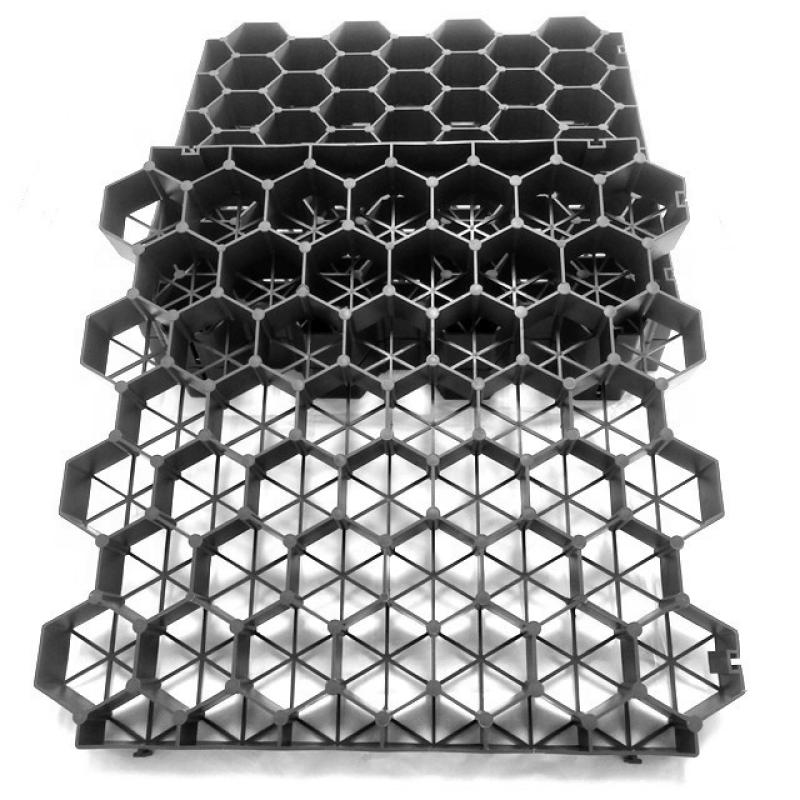

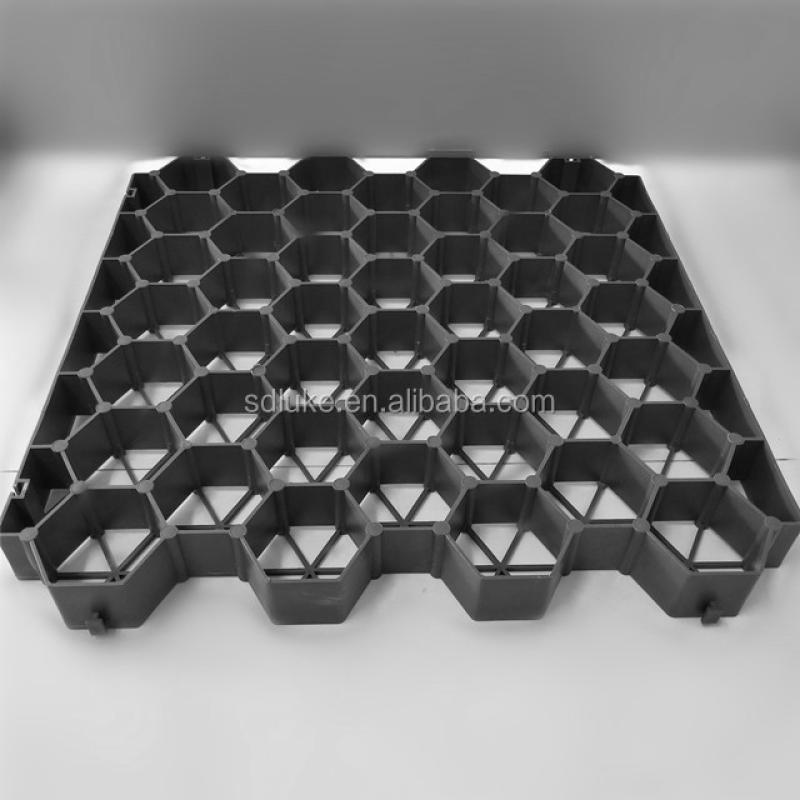

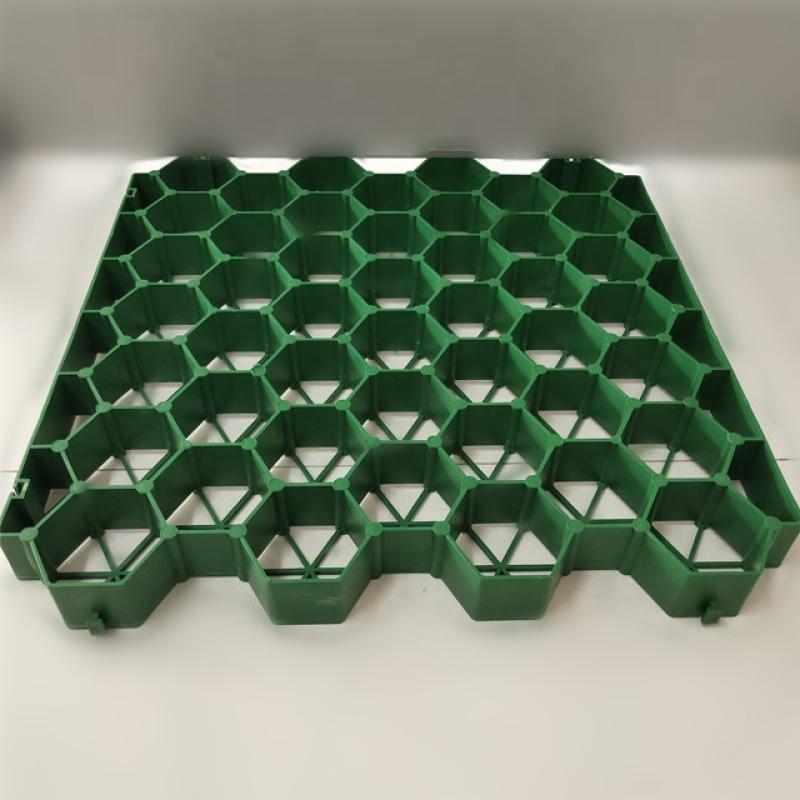

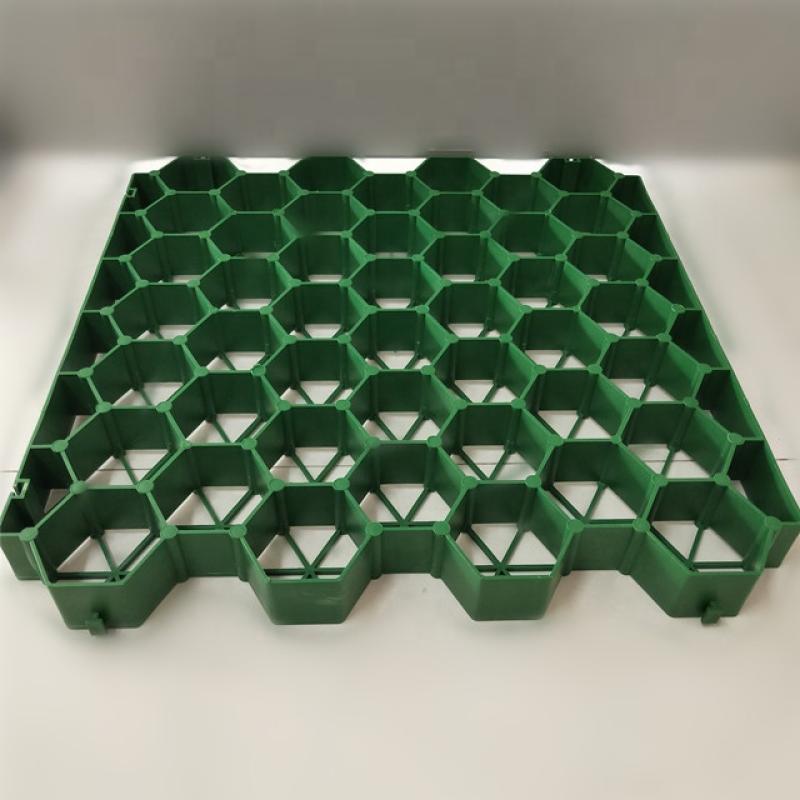

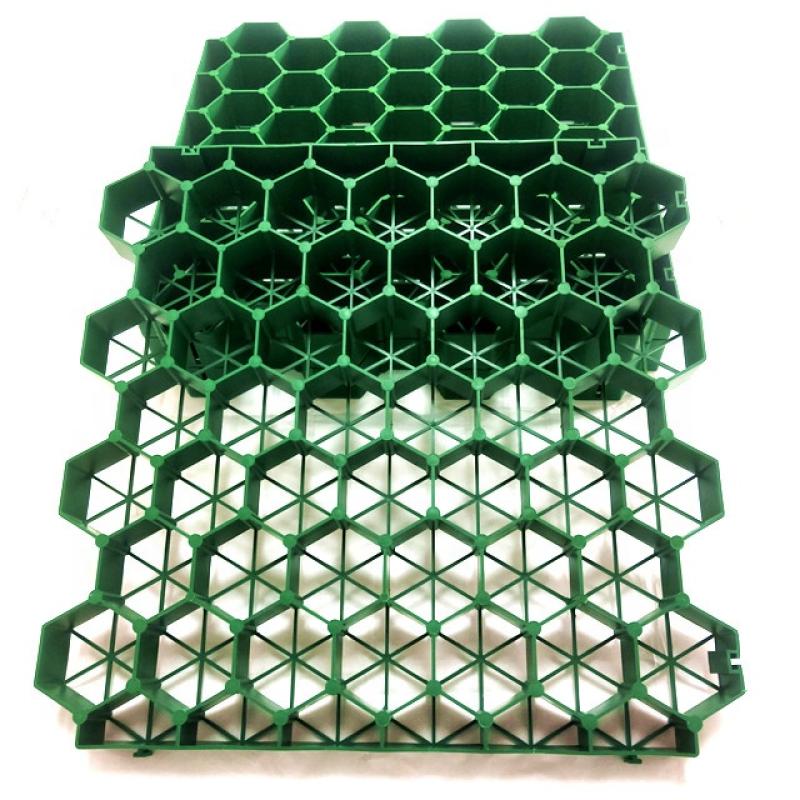

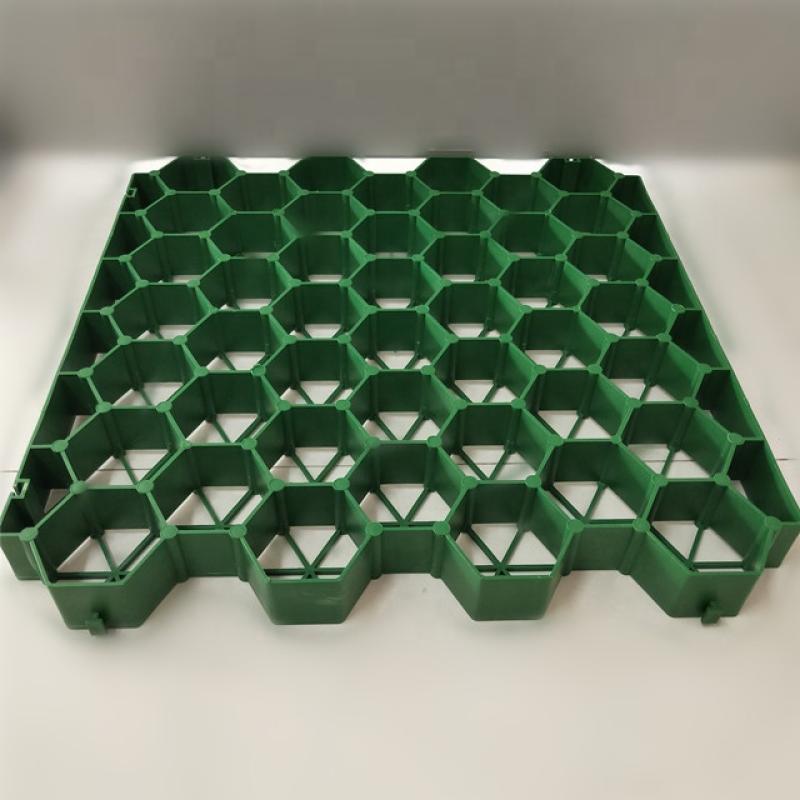

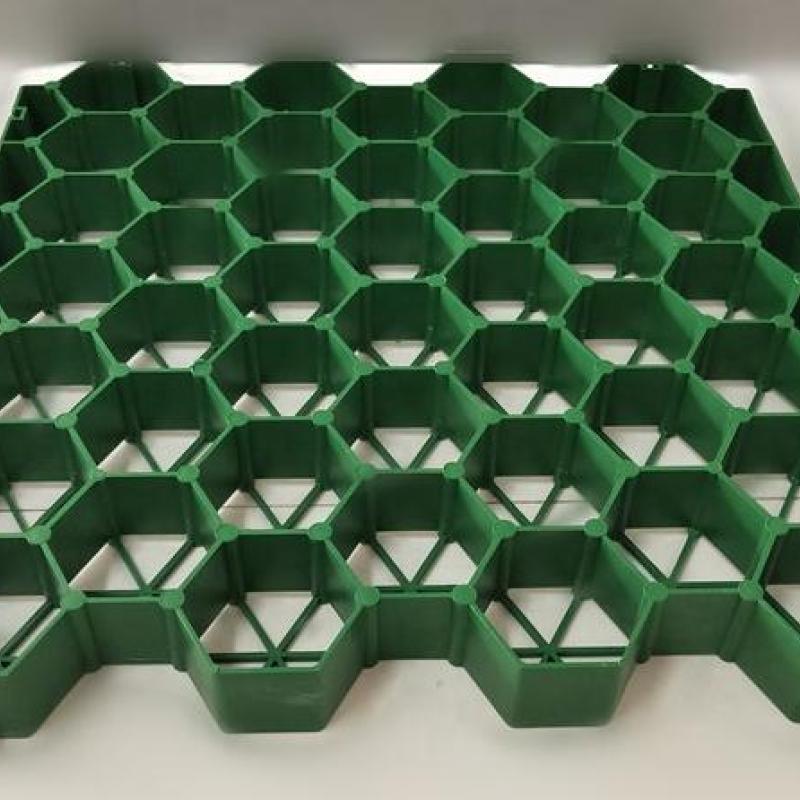

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Contact Now

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Contact Now

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Contact Now

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Contact Now

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Contact Now

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Contact Now

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Contact Now

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Contact Now

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Contact Now

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Contact Now