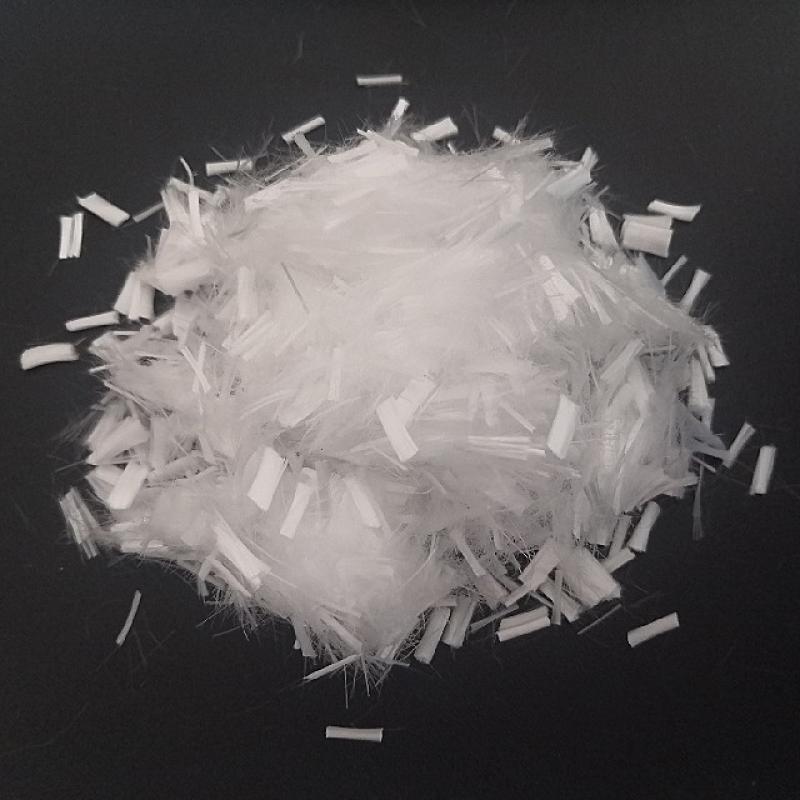

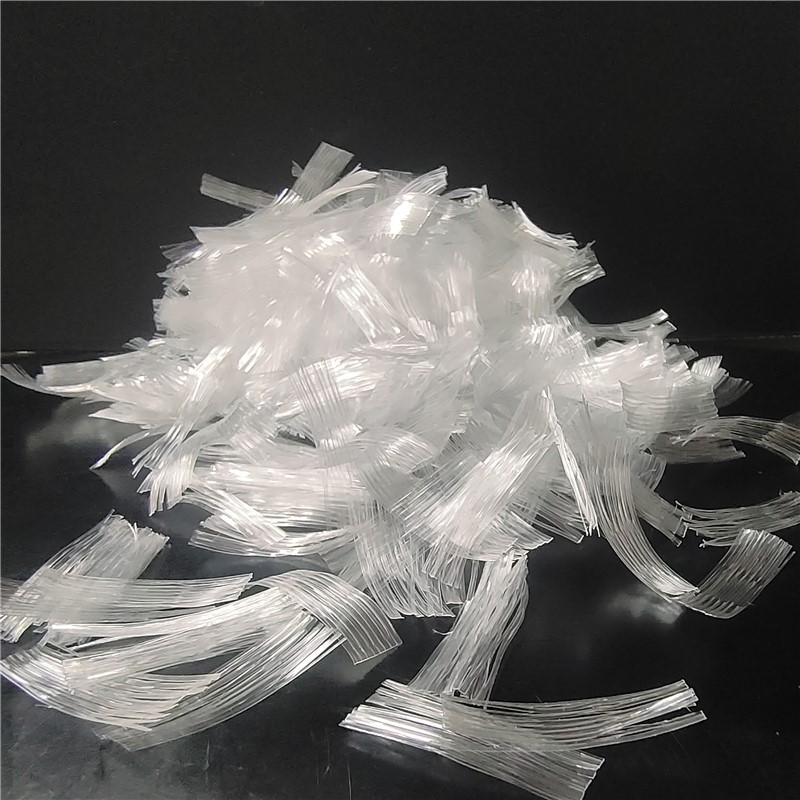

Polypropylene Synthetic Fiber for Shotcrete(wave shape Polypropylene Macro Fiber for Concrete)Polypropylene Synthetic Macrofiber for Concrete, like Shotcrete, replace steel fiber.It has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

Product Details The filament Non-woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is a kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkali resistance and anti-aging.The wider opening size allows it has good permeability and filtration.ParameterWeightg/m2100150200250300350400450500600800Weight Variation%-6-6-6-5-5-5-5-5-4-4-4Thicknessmm0.81.21.61.92.22.52.83.13.44.2

Contact Now

Concrete Reinforced Twisted Polypropylene FiberAs an admixture of concrete, bundle twisted fiber is applied more and more to concrete, which can enhance the cracking resistance of concrete and increase the bearing capacity of concrete.

Contact Now

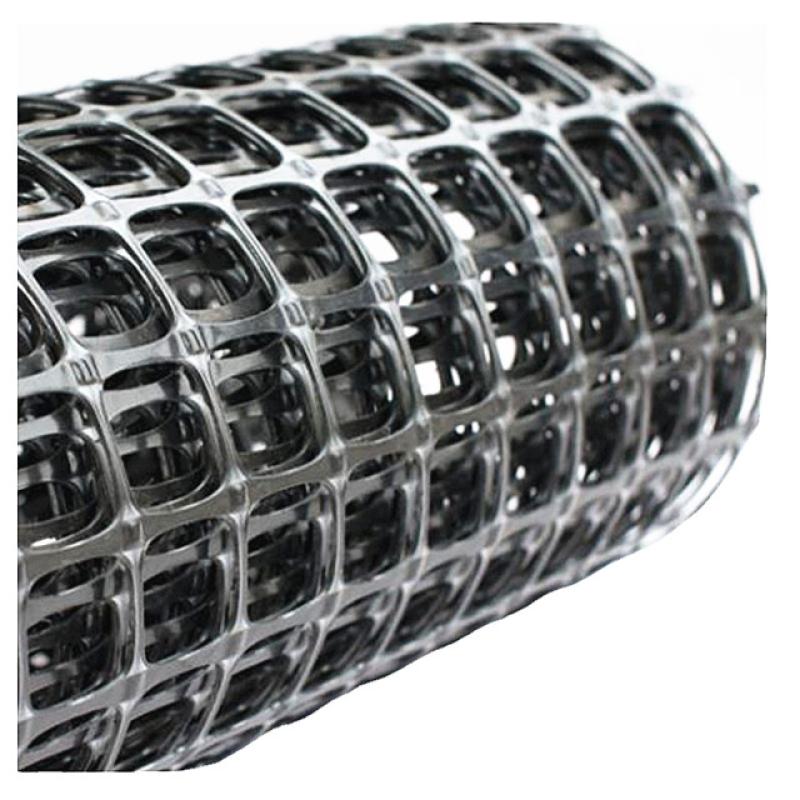

Product DetailsPlastic geogrid includes biaxial geogrid and uniaxial geogrid according to its structure.Biaxial plastic geogrid is made of polyethylene or high density polyethylene as the main raw material through the processes of hot-melt extrusion, vertical and horizontal stretching to form a high strength reinforced square mesh structure.

Contact Now

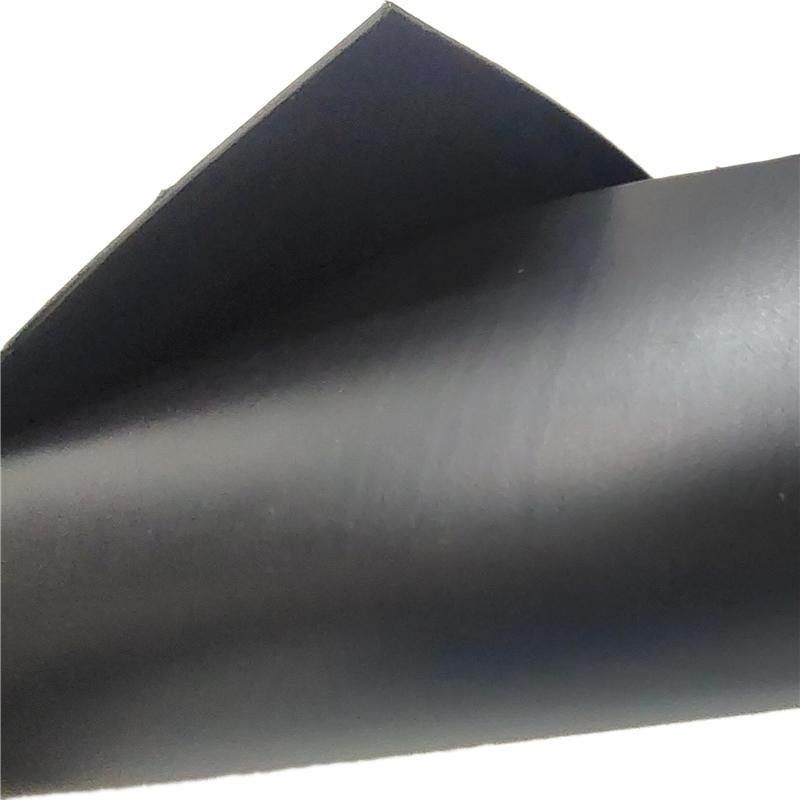

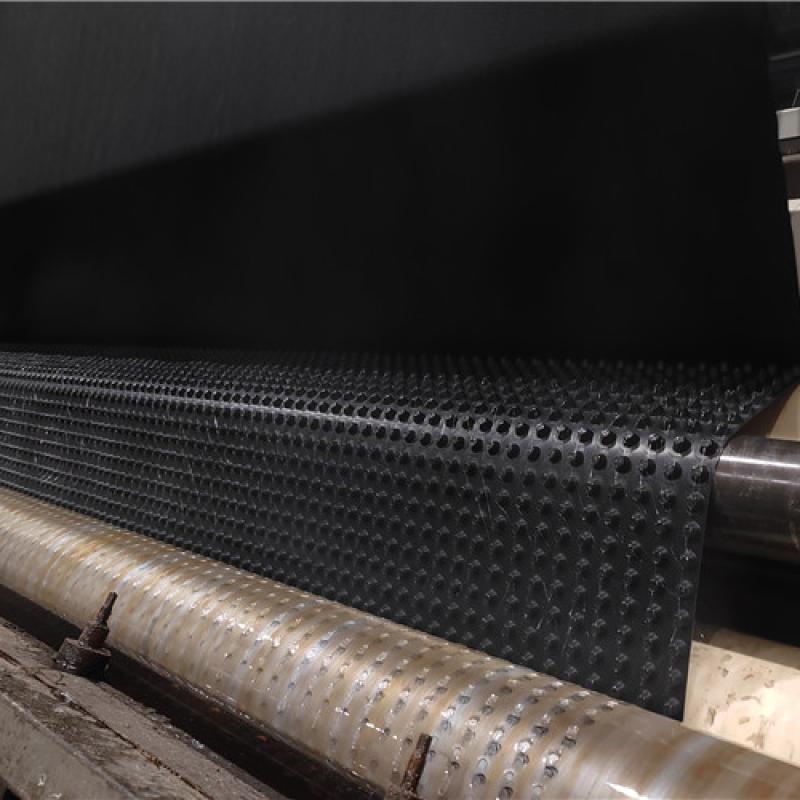

High Quality Waterproof HDPE GeomembranesShandong Luke Composite Materials Co., Ltd. is a professional company specializing in the production and sales of geomaterials. The company mainly produces and operates geotextile, geomembrane, drainage plate, geoglage, grid room, three-dimensional geoglage mat, geoglage mat, composite drainage net, grass grid, etc.Shandnong Luke Composite Co;LTd.

Contact Now

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Contact Now

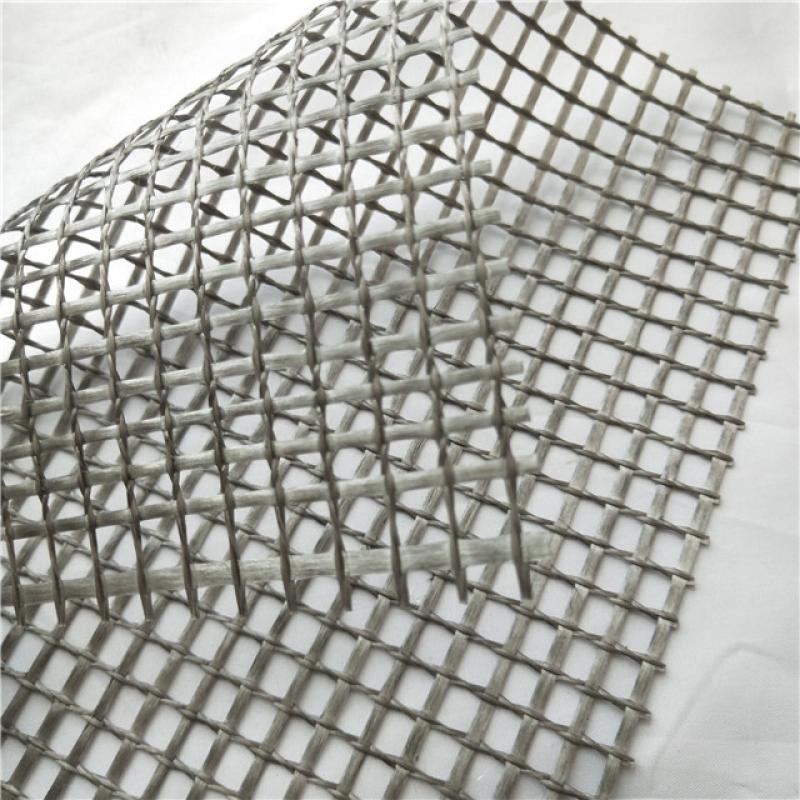

Hot Sale Reinforced Fiberglass Alkali Resistant Mesh Netting Fabric For ConcreteFiberglass mesh is fiberglass leno cloth because the substrate, the anti-emulsion polymer coating after immersion, which has appropriate Alkali resistance, flexibility and robust tensile energy, it is able to be extensively utilized in exterior insulation finishing system (eifs), roofing System, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass mesh is mainly alkali-resistant fiberglass fabri

Contact Now

product introduction Concrete PP fiber is a polypropylene as the main raw material, adopting unique manufacturing process to make high strength bundle mono-filament fiber. Join concrete (or mortar) can effectively control concrete (or mortar) micro-cracks which is caused by plastic shrinkage,temperature changes and other factors,to prevent and inhibit the formation and development of cracks, greatly improved crack resistance of concrete, impact resistance and seismic capacity. Length: for motor: <12 mm; for concrete: >12 mmCompounding amount

Contact Now

LUKE Polypropylene Mesh Fiber For ConcreteShandong Luke Composite Co., Ltd. is located at the foot of the beautiful Mount Tai. We now mainly produce and sell concrete anti-cracking fiber, anti-seepage geotechnical materials. Concrete anti-cracking fibers mainly include:polypropylene pp fiber, polypropylene PP mesh fiber, PAN fiber,high strength and high modulus polyvinyl alcohol fiber(PVA fiber),water-soluble PVA fiber, imitation steel fiber, polypropylene twisted bundle pp fiber,curved pp macro fiber, steel fiber, etc.

Contact Now

Product Details China Supplier PP Polypropylene Twist Fibers for Concrete ReinforcementPolypropylene Twist Macro Fiber is developed for replacement of steel fiber, with polypropylene as its raw material;It is produced by special drawing twisting and surface treatment.Compared with steel fiber, it has advantages of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to the mixing equipment.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic M

Contact Now