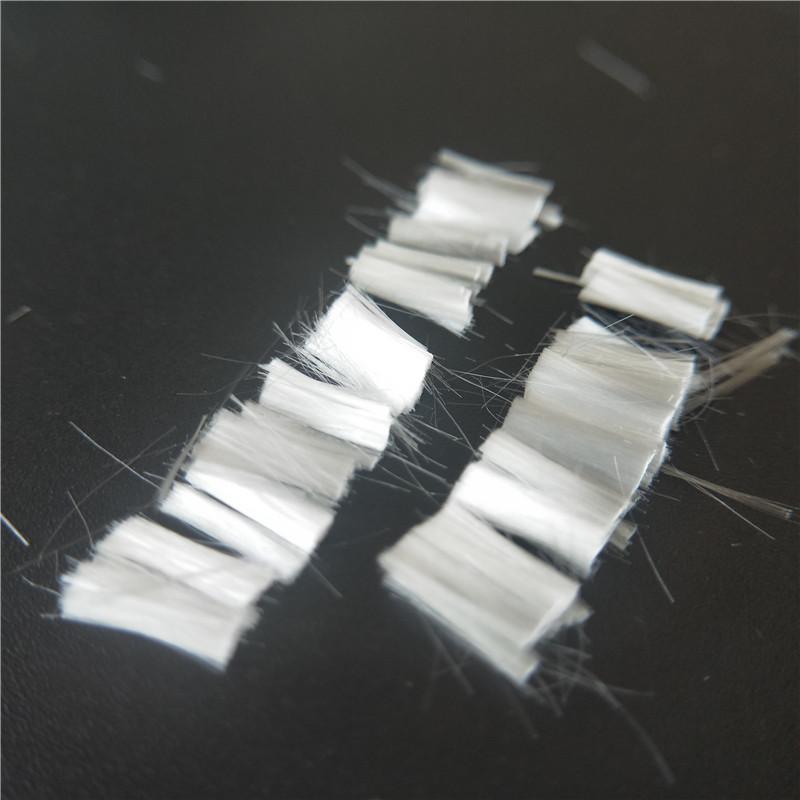

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Contact Now

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Contact Now

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contact Now

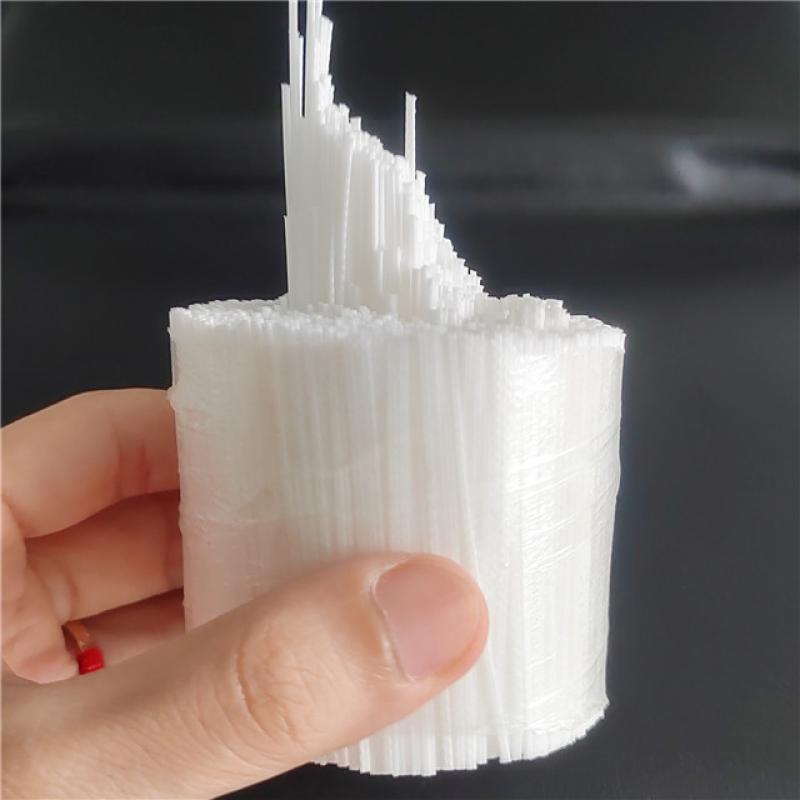

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Contact Now

Product DetailsIn the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete, namely steel fiber reinforced concrete.Compared with general concrete, steel fiber concrete has great improvement in tensile strength, flexural strength, abrasion resistance, impact resistance, fatigue resistance, toughness, crack resistance and antiknock performance, because large number of very minute steel fiber is evenly dispersed in the concrete and has a large contact area with concrete, therefore,concrete strength is impro

Contact Now

Polypropylene PP Concrete Cement Mesh Fibrillated FiberThis is Fibrilled Mesh Polypropylene Fiber for Concrete.It appears net-like structure with many monofilaments connected.ApplicationConcrete pavement,deck,airport runway,factory horizon. Shotcrete projects such as tunnel,mine wall,roof.Irrigation work such as river,dam.Military protection,terminal revetment, bridge pier.Concrete precast

Contact Now

Product Details Twisted package pp fiber is evolved for replacement of metallic fiber. With polypropylene as its uncooked fabric,it is produced via special drawing twisting and floor remedy. In comparison with metal fiber, it has advantages of acid, alkali resistant, terrific tensile, easy dispersing, convenience for creation and no damage to the integration device. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwist

Contact Now

With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.Application1. Surface of road and highway.2.

Contact Now

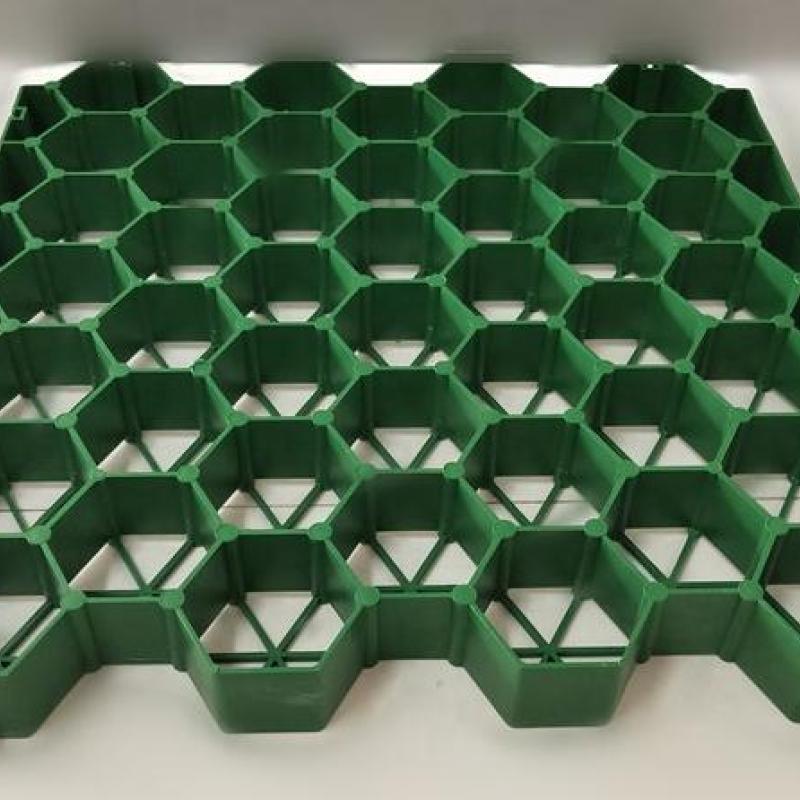

Product DetailsHDPE Geocell is made of a new type of high strength geosynthetic, which is popular with both domestic and abroad, in accordance with GB/T 19274-2003 implementation of the standards, which welding the strengthened HDPE sheets by the high-power ultrasonic and forming to be a structure of three-dimensional reticular formation which is easily folding and convenient for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,

Contact Now