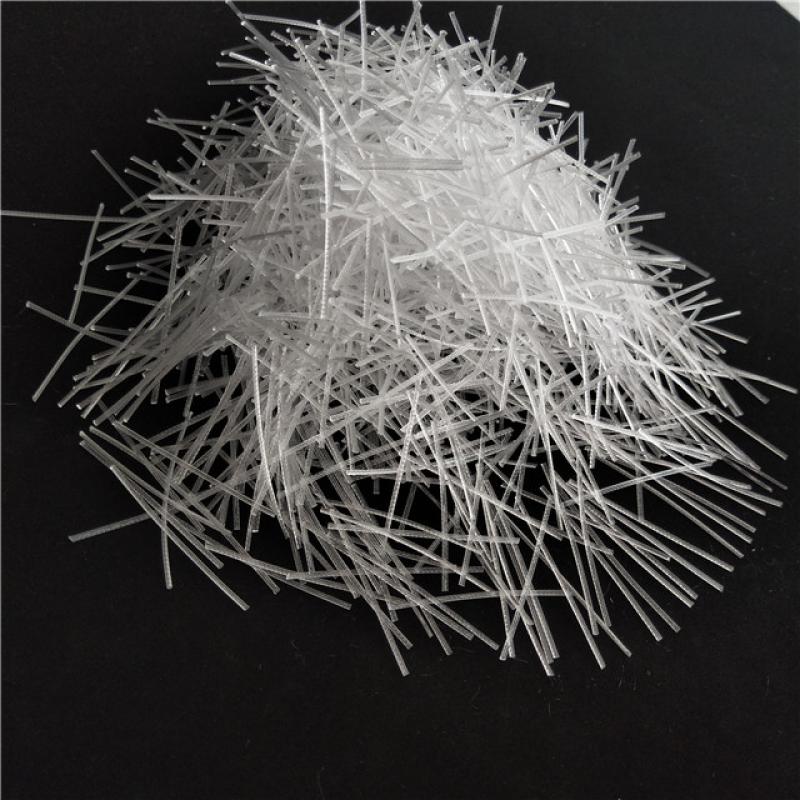

4 MM -19 MM Polypropylene PP Concrete Reinforced Fibers Polypropylene fiber can improve the adhesion of concrete, reduce cracks of concrete in the early stage. As our experiments, only 0.1% fibers by volume can improve the cracking resistance by 70%, and the impermeability increases by 60%-70%. PP fibers are chemically stable, it has excellent corrosive resistance to expand the self-life of your projects. PP fiber increases impermeability, only 0.9Kg/m3 PP fibers can improve it by 70%. The light-weight (0.91 density) of PP fib

Contact Now

Bundle Reinforced Polypropylene Twisted Fiber Concrete FiberBunched twisted reinforced polypropylene fiber is a kind of high performance fiber used in construction engineering. It can be used in construction projects instead of steel fiber. In addition to the characteristics of ordinary steel fiber, it has more advantages in concrete structures. Bunched and twisted polypropylene fiber is made of polypropylene as raw material.

Contact Now

Fiberglass Mesh FabricFiberglass Mesh is fiberglass leno fabric as the substrate, the anti-emulsion polymer coating after immersion, which has goodalkali resistance, flexibility and strong tensile strength, it can be widely used in exterior insulation finishing system (EIFS), roofing system, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass mesh is mainly alkali-resistant

Contact Now

Polypropylene Engineering Macro FibersWith the development of construction industry and the improvement of cement technology,the application of polypropylene engineering macro fibers is widely used in construction engineering.Polypropylene engineering fiber is a synthetic fiber made from polypropylene as the main raw material through a special process.

Contact Now

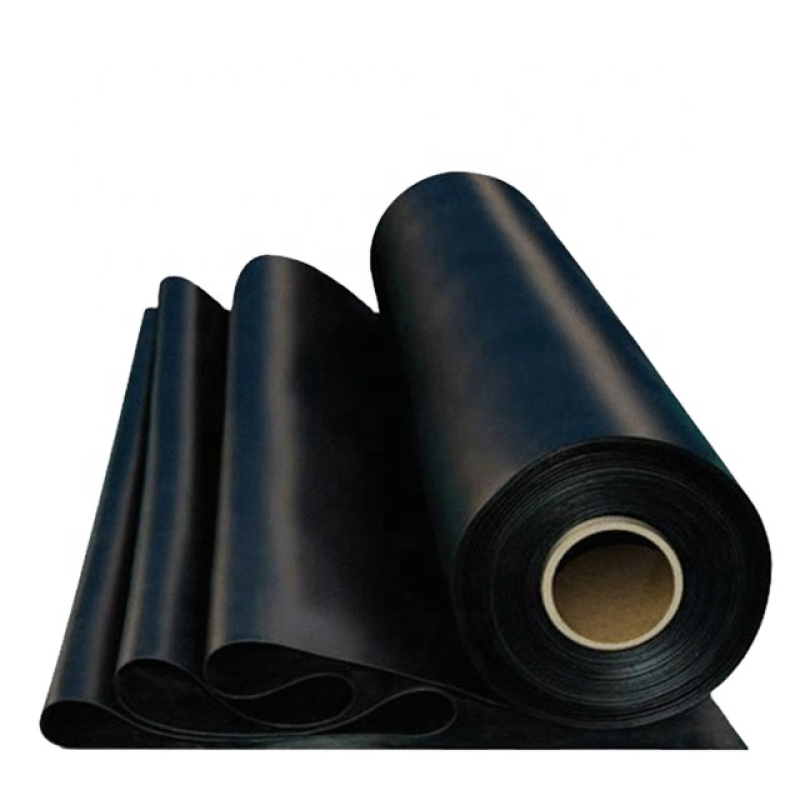

200gsm Polypropylene Polyester Nonwoven GeotextileThe needle punched non woven geotextile is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness.Our commonly used geotextiles are 200g/m2,300g/m2,400g/m2, and custom geotextiles.

Contact Now

40 MM High Performance Structural Synthetic Macro FibersProduct Details Concrete pp fiber is made by a hundred% virgin polypropylene,adopting unique production system to make high power bundle monofilament fiber. When the fiber is positioned into the concrete,concrete (or mortar) can efficaciously manipulate concrete (or mortar) Micro-cracks which is caused by plas

Contact Now

Concrete Fiber Polypropylene PP Fiber MeshPolypropylene mesh fiber is a kind of polypropylene particles as raw material, which is specially processed and treated. Add to the concrete base material. After stirring, the monofilament fiber or mesh structure fiber is fully opened, forming a chaotic support system inside the concrete. Polypropylene pp fiber mesh can effectively control the early plastic shrinkage and settlement cracks of concrete and cement mortar.

Contact Now

600Mpa Polypropylene Macro Fiber For ConcretePolypropylene macro fiber with a tensile strength of 600Mpa is added to the concrete,and the concrete becomes a concrete material with high tensile strength and ductility.As a reinforced polypropylene fiber ,it plays an important role in improving its performance.Reinforced fiber can significantly improve the crack resistance of concrete. The strength of ordinary concrete is obviously low when it is pulled, and it is easy to produce cracks.

Contact Now

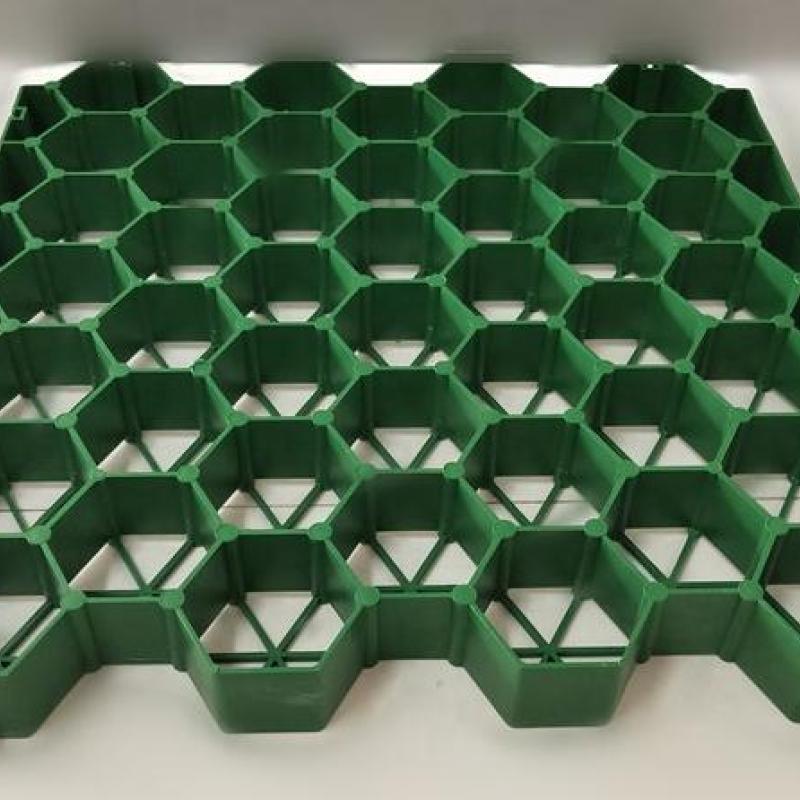

Product Details3D geomat is sort of a gourd network 3-dimensional structure for the planting soil, unfastened and flexible, with a ninety% space filling soil, gravel and exceptional stone, plant roots can interfere, at ease, orderly and balanced increase after developing grass mat, turf, soil.The floor tightly together, because the plant roots deep below the floor of 30 - forty cm, forming a protective layer of green composite strong.Earlier than the turf grows, it protects the surface of the soil from rain and wind.It is able to firmly hold the seeds evenly dispensed at the slope, from the wi

Contact Now

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Contact Now