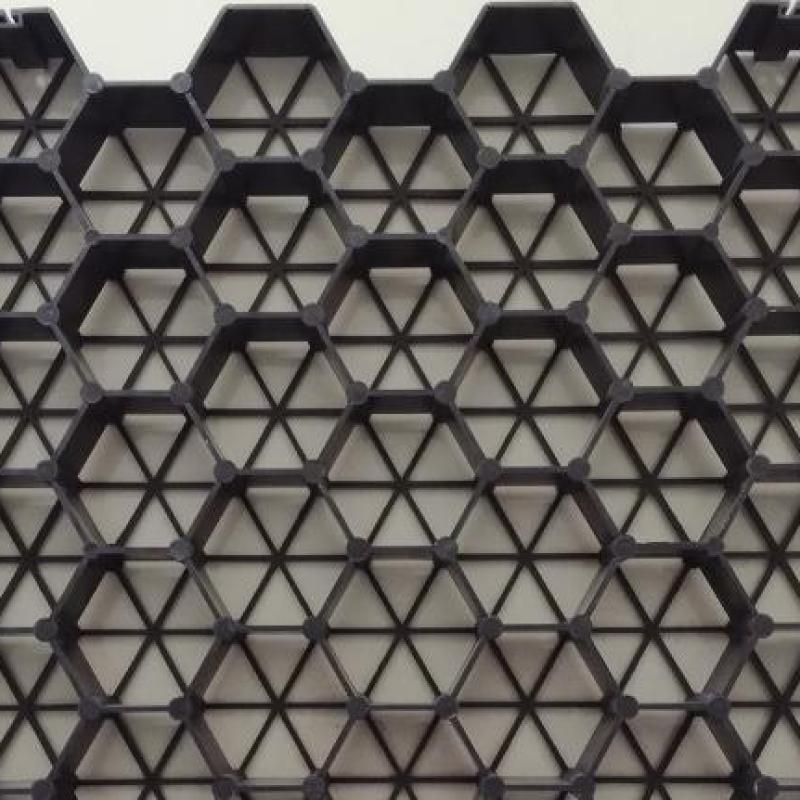

Product DetailsComposite drainage net is made from geonet bonding layers of geotextile which mixes the homes of geotextile filtration and geonet drainage and protection,presenting entire“inverted filter drainage to guard”impact.drainage nets core is extruded by high density polyethylene uncooked substances adding carbon black and ultraviolet and antioxidant stabilizer.the interlaced internet paperwork into a drainage channel which has excellent vertical drainage residences.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6Hydraulic Conducti

Contact Now

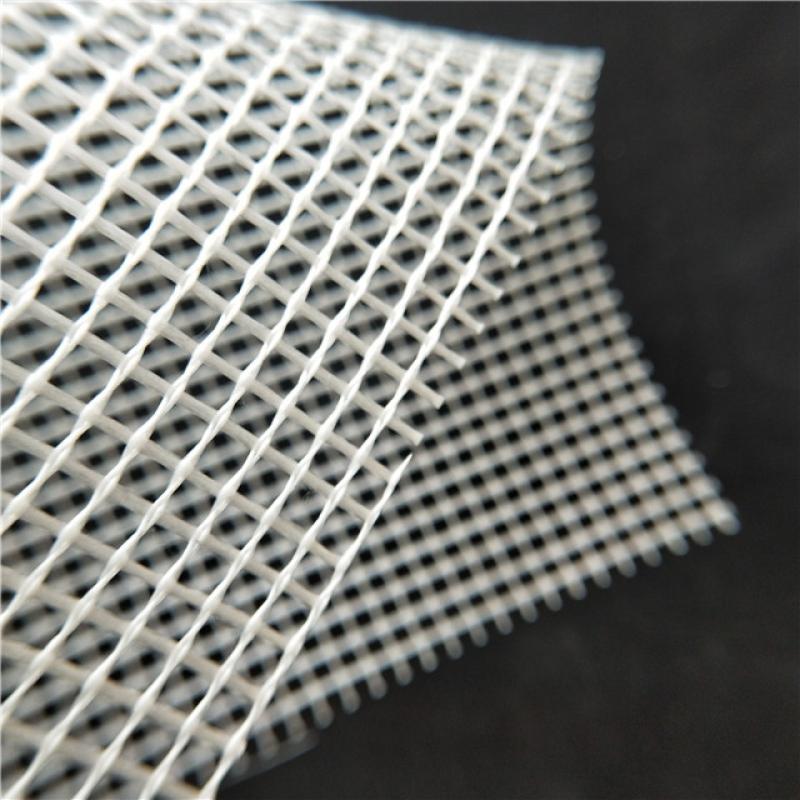

Fiberglass Mesh FabricFiberglass Mesh is fiberglass leno fabric as the substrate, the anti-emulsion polymer coating after immersion, which has goodalkali resistance, flexibility and strong tensile strength, it can be widely used in exterior insulation finishing system (EIFS), roofing system, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass mesh is mainly alkali-resistant

Contact Now

Product DetailsIn comparison with fashionable concrete, metal fiber concrete has extremely good development in tensile energy, flexural strength, abrasion resistance, effect resistance, fatigue resistance, sturdiness, crack resistance and antiknock overall performance, because large huge form of very minute steel fiber is calmly dispersed inside the concrete and has a huge touch location with concrete, therefore,concrete electricity is improved in all tips and the various performances of concrete are considerably stepped forward.ParameterMaterialCarbon steelTypeWaveLength(mm)20mm-60mmEquivalen

Contact Now

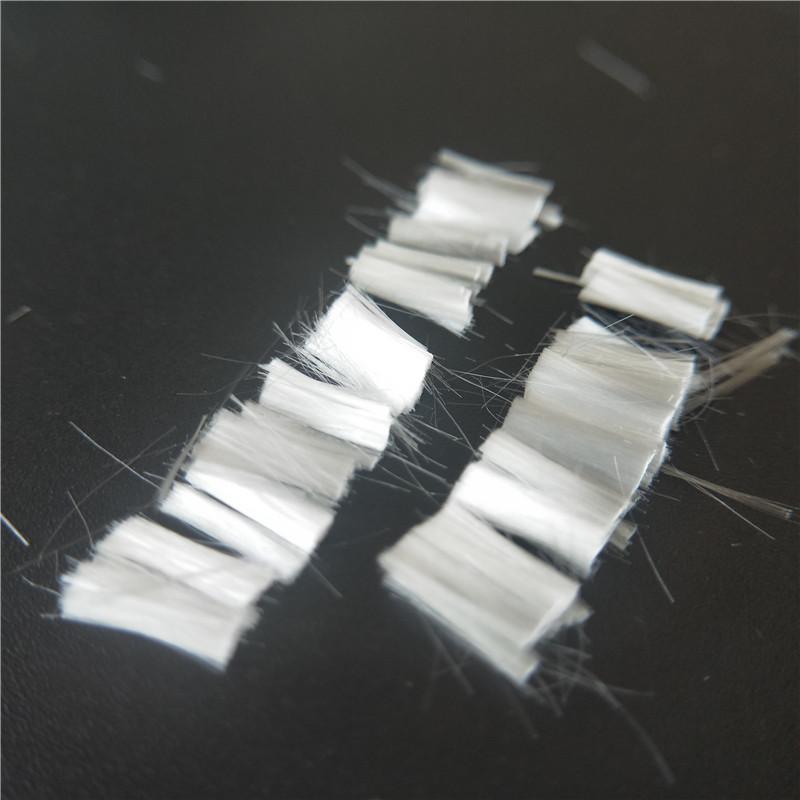

Product Details When the fiber is put into the concrete, the horizontal structure in fiber monofilament may be destroyed inside the course of stirring attributable to friction and rubbing, and the fiber monofilament or net-like shape will completely stretch, consequently the concrete is reinforced by using a remarkable quantity of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)100±50Material100% polypropyleneCrack Elongation(%)≥16Water-AbsorbencyNoMelting Poi

Contact Now

80-160 G Fiberglass Mesh Fabric For Wall Construction Fiberglass mesh is woven by means of c-glass fiberglass yarn, and then coated by way of alkali resistant glue.specifically has excessive property for Acid-resistant and excessive electricity for concrete reinforcement.Fiberglass mesh has been the primary simple materials for structures, and welcomed in europe.1.Factory supply2.Quick deliver

Contact Now

Product DetailsWhen the fiber is positioned into the concrete, the horizontal shape in fiber monofilament may be destroyed inside the direction of stirring resulting from friction and rubbing, and the fiber monofilament or net-like shape will virtually stretch, therefore the concrete is strengthened by way of the usage of a exquisite amount of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)100±50Material100% polypropyleneCrack Elongation(%)≥16Water-AbsorbencyNoMelting Point

Contact Now

Bundle Reinforced Polypropylene Twisted Fiber Concrete FiberBunched twisted reinforced polypropylene fiber is a kind of high performance fiber used in construction engineering. It can be used in construction projects instead of steel fiber. In addition to the characteristics of ordinary steel fiber, it has more advantages in concrete structures. Bunched and twisted polypropylene fiber is made of polypropylene as raw material.

Contact Now

Product DetailsDimple Drain board is the use of foundation or blow molding method to produce high density polyethylene (HDPE) geomembrane, pressed on geomembrane pressure after the special craft the closed swelled the frustum of a cone shape, having a three-dimensional space and some support stiffness, liquid, gas can flow excreted within its plate.This is a latent many functions materials, the use of this plate can be easily constructed out of the overhead layer, using overhead layer formed drainage, exhaust passage, at the same time to use the overhead layer reaches low noise, vibration isol

Contact Now

Concrete PP fiber is a polypropylene as the main raw material, adopting unique manufacturing process to make high strength bundle mono-filament fiber.

Contact Now

Polypropylene Plastic Macro Fiber Concrete FiberAs concrete additives, polypropylene macro fiber has numerous advantages in concrete engineering. By adding 100% polypropylene macro pp fiber to the concrete, it can effectively control the formation and expansion of concrete cracks and ensure the integrity and stability of concrete structures in the project. So, pp macro synthetic fiber has strong crack resistance.

Contact Now